ULTRASONIC SCREENS

Enhance efficiency, reduce downtime, and improve product quality with Ultrasonic Screens from Compass Wire Cloth.

The Ultrasonic Screens have a patented process that boosts throughput and addresses the persistent challenges of material processing, such as blinding and pegging.

Retrofit any size screen with ultrasonics to achieve significantly improved screening performance, consistency, and higher capacity utilization.

Enhanced, Tailored Performance with Ultrasonic Screens

The patented Frequency Variation Method has a variety of benefits to keep your machines working well with minimal downtime.

- Maximum Ultrasonic Excitation Efficiency

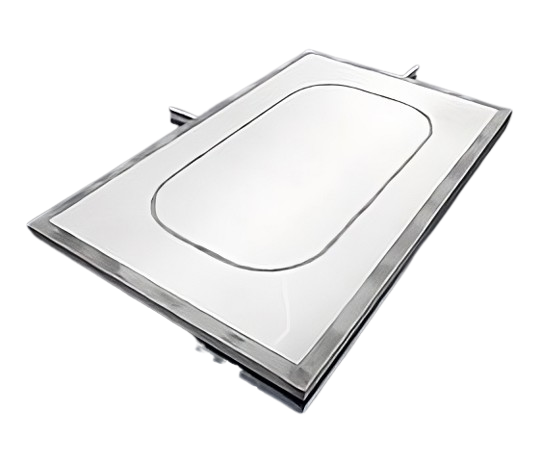

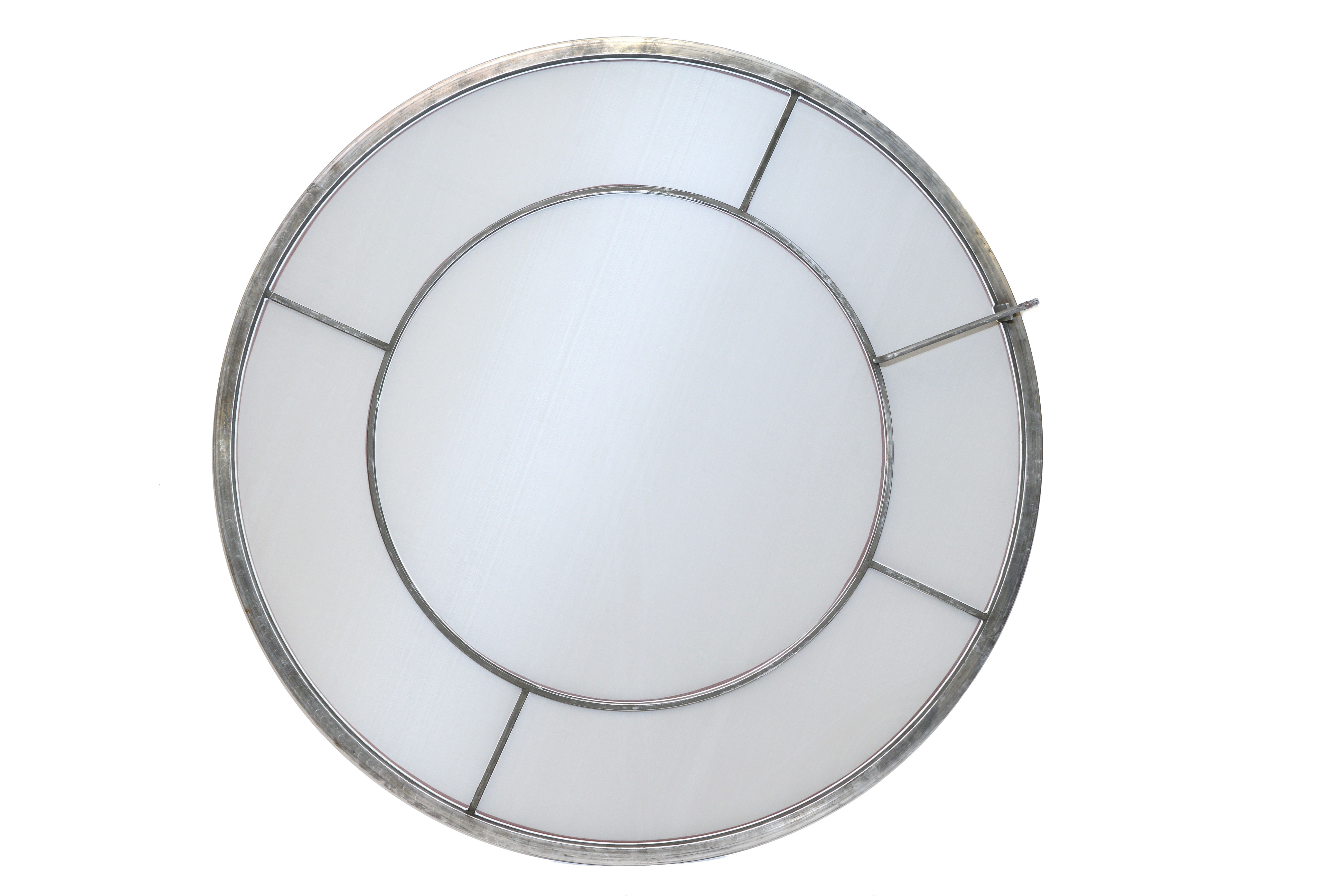

- Versatility for tumbler and vibrating screening machines, centrifugal sifting machines, rectangular and round screens, laboratory screens, and more

- Increased screening throughput while reducing dynamic stress on the mesh

- Increased longevity of the screening mesh

- Enhanced hygiene and minimized contamination risks

- Custom-made, complete package and retrofitted to your machine where necessary

- External remote control for ease of use

This innovative technology intelligently searches for the optimal operating point, enabling smooth ultrasonic vibrations across various screen geometries without altering the structure of the application itself to provide an enhanced performance tailored to your specific needs.

The design also includes a converter located outside the screening area, ensuring no direct product contact and thereby enhancing hygiene and minimizing contamination risks.

Ultrasonic Screen Specifications

- Single-panel design

- Stainless steel

- ATEX Certified

- Advanced PLC Interface

- Customizable or retrofitted to your requirements

Complementary Products and Accessories

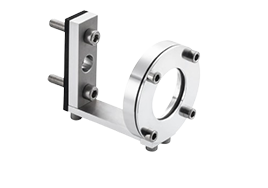

Converter

C32-HP1

Converter Mount

Ultrasonic Clamp

Generator

RF Cable