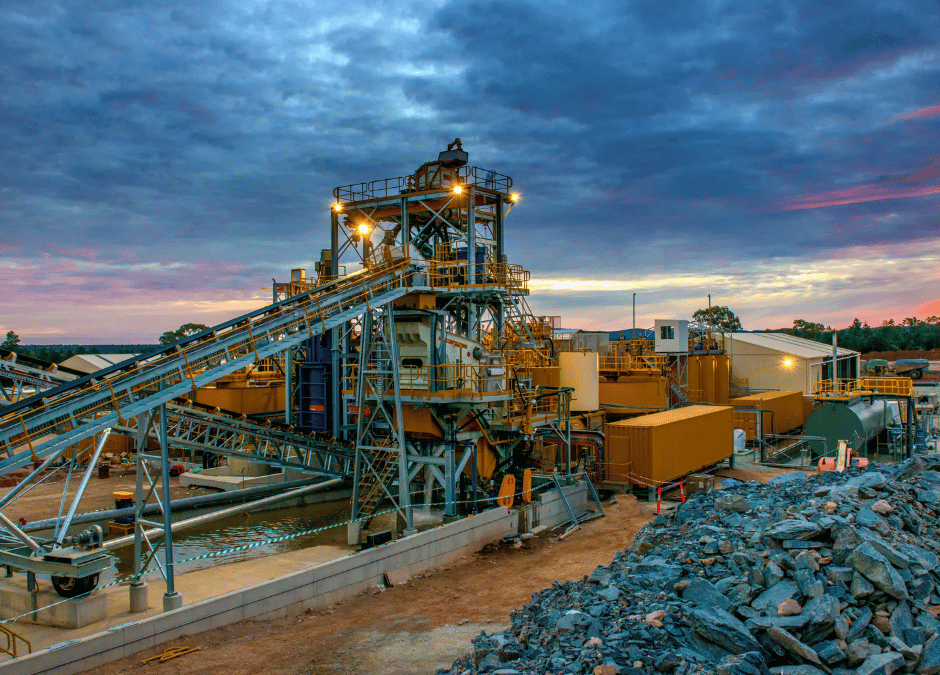

In the world of aggregate processing, achieving the perfect balance between production efficiency and product quality is key. Whether you’re working with gravel, sand, limestone, or any other aggregate material, maintaining the sizing and quality of your finished product is crucial. But how do you do that without sacrificing throughput? The answer lies in selecting the right screening equipment and ensuring your screens are optimized for your specific operation.

One of the most common challenges in aggregate screening is avoiding issues like pegging and blinding. Pegging occurs when stones block the openings in the screen, while blinding happens when fine particles coat the screen’s surface, reducing its effectiveness. These problems not only slow down your production but can also compromise the quality of your finished product by allowing unwanted flakes and slivers to slip through.

To keep your production rates high and your product quality at its best, it’s essential to use screens that are designed to handle the specific characteristics of your material. Clean screens with wires that vibrate independently are particularly effective in preventing pegging and blinding. These screens allow for more efficient separation of unwanted material, ensuring that only right-sized aggregate makes it through.

At Compass Wire Cloth, we specialize in helping you find the best screen style for the aggregate material you’re processing. This means choosing the right size openings for your screen, along with the appropriate weave and wire size. Whether you’re dealing with coarse material that requires larger openings or fine material that needs a tighter weave, our team can guide you to the perfect solution.

The right screen can make all the difference in your operation. By selecting a screen that’s tailored to your material, you can maintain consistent product sizing, enhance throughput, and reduce downtime caused by pegging and blinding. This not only boosts your production efficiency but also ensures that your finished product meets the highest standards of quality.

When you partner with Compass Wire Cloth, you’re not just getting a screen—you’re getting a solution that’s customized to your needs. Our expertise in screen selection helps you produce right-sized aggregate material efficiently and reliably. Let us help you optimize your screening process, so you can keep your operation running smoothly and your products meeting the exacting standards of your customers.

- Triangular shaped opening

- Resilient to damage from oversized material

- Most accurate for sizing

- Diamond-shaped openings

- Accurately size dry or damp material

- Also available in High Carbon wire

- Herringbone weave pattern

- Prevent roots, grass, and other debris from clogging screen surface

- Used where gradation from raw to finished is not great