When it comes to optimizing your screening process, keeping your mesh clear of obstructions is key. Obstructed screens can lead to decreased efficiency, increased downtime, and ultimately, lower production quality. That’s where Compass Wire Cloth’s Self-Cleaning Sandwich Screens come into play—a revolutionary solution designed to keep your screens clean and your operation running smoothly.

How Self-Cleaning Sandwich Screens Work

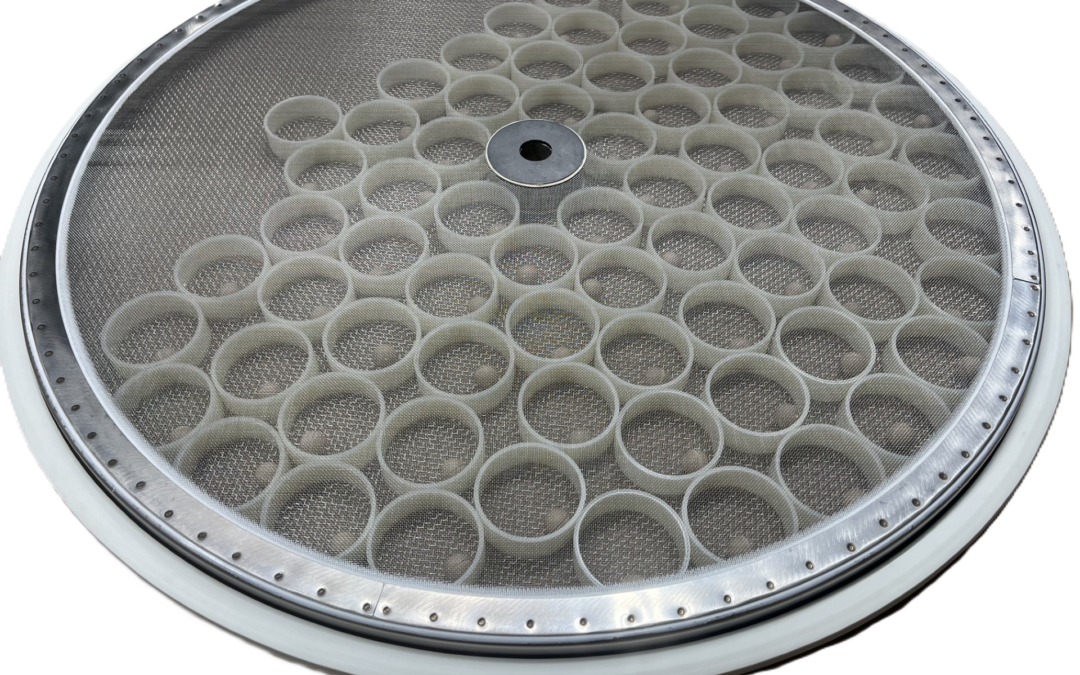

Sandwich screens are ingeniously designed to prevent materials from clogging the mesh, ensuring consistent and efficient screening. They achieve this by applying gentle vibration against the bottom of the screen using a combination of Nylon Sliders and/or Rubber Balls. These components rotate freely around the screen’s surface, providing even coverage across the entire screen. As they move, they dislodge any particles that might otherwise stick to the mesh, preventing blinding and keeping your operation at peak performance.

One of the key advantages of sandwich screens over traditional clean ring assemblies and ball trays is the containment of the de-blinding sliders and balls between the two layers of mesh. This design simplifies maintenance by allowing for faster screen changeouts, whether for cleaning or switching to a different production run. By minimizing downtime and maintenance efforts, sandwich screens can significantly boost your operational efficiency.

Cost-Effective and Long-Lasting

Another major benefit of using sandwich screens is their cost-effectiveness. Compass Wire Cloth offers epoxy-bonded mesh sandwich screens that can be returned and re-screened multiple times before the sliders, balls, and support mesh need to be replaced. This reusability translates into substantial cost savings, as you won’t need to purchase new screens as frequently. The ability to rescreen and maintain the same high level of performance makes sandwich screens a smart investment for any operation.

Customization for Your Specific Needs

Every screening operation is unique, and Compass Wire Cloth understands that one size doesn’t fit all. That’s why our sandwich screens are customizable to meet the specific needs of your equipment and materials. Some machines may require a center hole or spacer to handle the material load on the screen effectively. For most applications, incorporating a center spacer or a center spacer with a hole is recommended to maintain consistent height between the two mesh layers and to allow the sliders to move freely. This customization ensures optimal performance and longevity for your screens.

Need Help? We’re Here for You!

Choosing the right screening solution can make a significant difference in your production process, and Compass Wire Cloth is here to help you make the best choice. If you have any questions about how our Self-Cleaning Sandwich Screens can benefit your specific application, our knowledgeable team is ready to assist. We’ll guide you through the selection process, ensuring that you get the most effective and efficient solution for your needs.

Maximize your screening efficiency and reduce downtime with Compass Wire Cloth’s Self-Cleaning Sandwich Screens. Contact us today to learn more about how we can help keep your operation running smoothly.