Self Cleaning Sandwich Screens

Self Cleaning Sandwich Screens

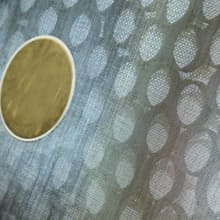

Sandwich Screens are designed to keep the mesh free from obstruction from materials. Gentle vibration are applied against the bottom of the screen with a combination of either Nylon Sliders and/or Rubber Balls. These components gently rotate around the screen to provide even coverage for the entire screen. (Balls and Sliders highlighted in image)

The sandwich screens are an easier solution to manage than clean ring assemblies and ball trays as the de-blinding sliders and balls are contained between both layers of mesh. This allows for faster screen changeout for cleaning or production run changes.

Epoxy-bonded mesh sandwich screens can be returned and re-screened often many times before the sliders and balls and support mesh needs to be replaced, which is significantly less costly than purchasing new screens.

Screens designed specific to your needs

Some machines require a center hole or spacer based on the material load on the screen. For most applications, a center spacer or center spacer with a hole should be used to maintain consistent height between the two mesh layers and allow the sliders to move freely.

If you have any questions about your application, we are happy to assist you!

Screens for all OEMs

Rubber and Neoprene Balls

Sleeves, Channel Rubber, Connectors

Ball and Slider Rings come in a variety of sizes